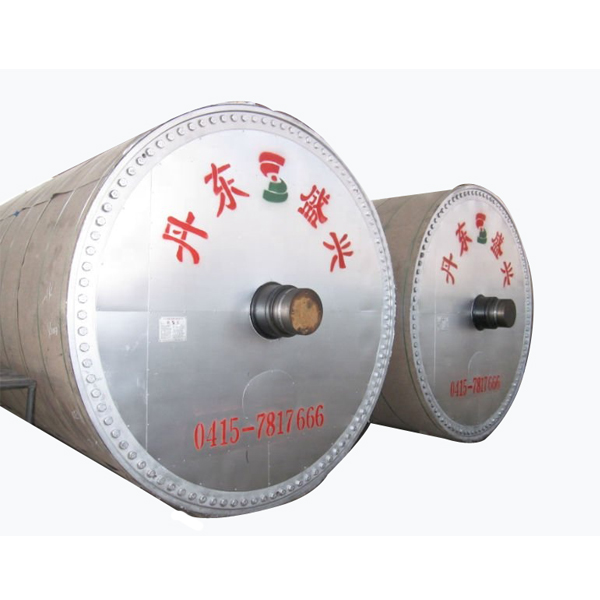

Cast Iron Yankee Dryer Cylinder

- Shengxing

- China

- 90 days

- 100 sets/90 days

Dandong Shengxing Paper Machinery Co.,Ltd established since 1985 and we had the experience of producing the cast iron yankee dryer cylinder over 35 years, and we are the pioneer in this industry.

https://youtu.be/1cpDtT6Xrcc Cast iron yankee dryer cylinder

A Yankee dryer cylinder is a pressure vessel used in the production of tissue paper. On the Yankee dryer cylinder, the paper goes from approximately 42-45% dryness to just over 89% dryness. In industry, MG cylinders or Yankee dryers are primarily used to remove excess moisture from pulp that is about to be converted into paper. The Yankee cylinder can be equipped with a doctor blade and sprayed with adhesives to make the paper stick. Creping is done by the Yankee's doctor blade that is scraping the dry paper off the cylinder surface thereby crêping the paper. The crinkle (crêping) is controlled by the strength of the adhesive, geometry of the doctor blade, speed difference between the yankee and final section of the paper machine and paper pulp characteristics.

All dryer cylinders, heads and journals are made of special cast iron. Separate journals are bolted onto the dryer heads. Dryer shells are ground on the outside and turned on the inside. All dryer journals with steam or condensate pipes have insulation sleeves. The inner surfaces have grooves for the stationary siphons. The front side ends of all dryers contain manholes.

Cast iron material are excellent in durability.This is because the free form flake graphite in the cast iron material ensured its high corrosion and erosion resistance. The cast iron also has good fatigue strength under the pressure roller forces. At the same time, cast iron itself has a good surface performance, does not need metal spraying treatment like steel dryer.

The parameter of the cast iron yankee dryer ccylinder

|

Diameter mm |

Design Pressure Mpa |

Material |

Hardness HB |

Face length mm |

Shell thick mm |

Roughness |

Working speed M/min |

|

1500 |

0.3-0.8 |

HT250-300 |

190-240 |

350-10000 |

20-30 |

0.2-0.4 |

200-1200 |

|

1800 |

0.3-0.8 |

HT250-300 |

190-240 |

350-10000 |

23-35 |

0.2-0.4 |

200-1200 |

|

2000 |

0.3-0.8 |

HT250-300 |

190-240 |

1350-8000 |

24-38 |

0.2-0.4 |

200-1200 |

|

2500 |

0.3-0.8 |

HT250-300 |

190-240 |

1350-8000 |

24-46 |

0.2-0.4 |

200-500 |

|

3000 |

0.3-0.8 |

HT250-300 |

190-240 |

1350-6000 |

28-54 |

0.2-0.4 |

200-600 |

|

3660-3680 |

0.3-0.8 |

HT250-300 |

190-240 |

1350-5000 |

33-65 |

0.2-0.4 |

200-1200 |

|

Press Roll 600-1650 |

/ |

HT250-300 |

/ |

1350-8000 |

50-150 |

/ |

200-1200 |

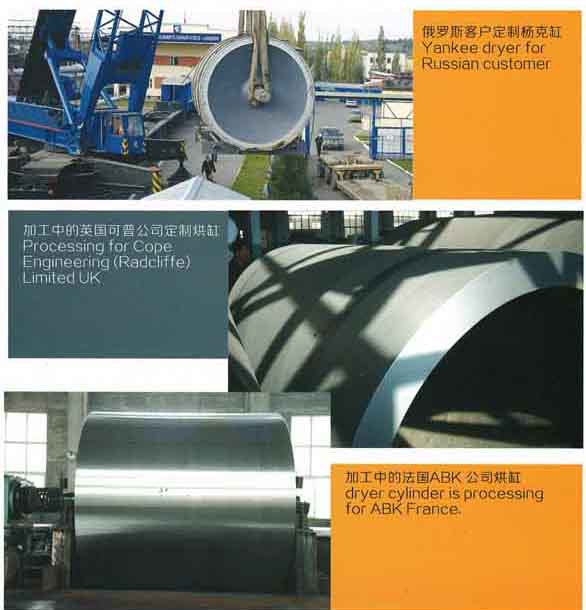

Yankee dryer cylinder for Russian customers.

Processing for Cope Engineerring Limited Uk

Dryer cylinder for ABK France.

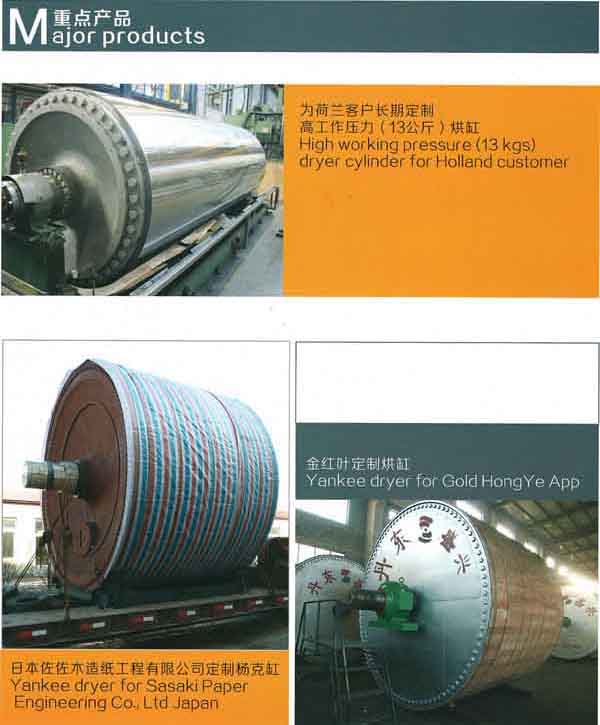

High working pressure 13kg dryer cylinderr for holland customer.

Yankee dryer cylinder for Sasaki Papper Engineering Co.,Ltd

Golden supplier for Voith

Exhibition in Indian Papar Machinery